1.Производственный процесс

Литой вариант: используется процесс литья. Металлические материалы нагреваются до расплавленного состояния, а затем заливаются в заранее изготовленную форму. После охлаждения и затвердевания формируется желаемая форма торцевой крышки.

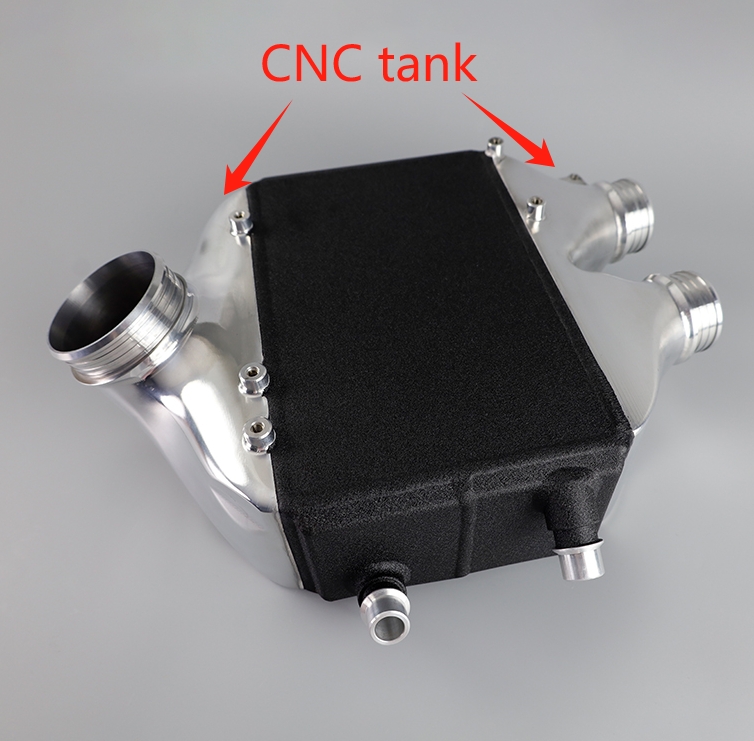

Версия с ЧПУ: используется технология числового программного управления (ЧПУ). Процесс включает использование запрограммированного станка для резки и формовки металлического материала.

2. Выбор материала

Литой вариант: Обычно используются такие материалы, как литейный алюминиевый сплав. Эти материалы обладают хорошими литейными свойствами, соответствующими требованиям литейного процесса, но их механические свойства относительно плохие.

Версия с ЧПУ: Обычно используются высокопрочные алюминиевые сплавы, такие как алюминиевый сплав 6061. Эти материалы обладают высокой прочностью и хорошей коррозионной стойкостью, что соответствует требованиям обработки на станках с ЧПУ, а также обеспечивает эксплуатационные характеристики резервуара.

3. Эксплуатационные характеристики

Литой вариант: Из-за ограничений производственного процесса могут быть внутренние дефекты, такие как газовая пористость и включения песка. Эти дефекты могут повлиять на прочность и герметичность бака. Кроме того, шероховатость поверхности литого бака относительно высока, что может создать некоторое сопротивление потоку охлаждающей жидкости.

Версия с ЧПУ: Поверхность гладкая, что может уменьшить сопротивление потоку охлаждающей жидкости и повысить эффективность охлаждения. Высокая точность внутренней структуры может лучше соответствовать требованиям двигателя к потоку и давлению охлаждающей жидкости, тем самым повышая производительность двигателя.

4. Стоимость и цена

Литой вариант: Стоимость изготовления относительно низкая и подходит для массового производства. Его цена обычно более доступна, что дает ему определенное ценовое преимущество на рынке.

Торцевая крышка интеркулера с ЧПУ: Из-за высокой точности обработки, относительно низкой эффективности производства и необходимости использования высокоточного оборудования с ЧПУ себестоимость производства выше.